3.63m Headboard - A Masterclass in Details

When interior design firm, Collective Designs tasked us with crafting a custom-made bed with a sprawling 3.63-meter wide headboard, we quickly realised there’s little room for oversight.

This wasn’t just about building a bed; it was about engineering a piece that, from the laminated carcass to the motorised storage, meets practical demands with design ambition. Working with the talented team at Collective Designs, we had more than a few nuances to navigate.

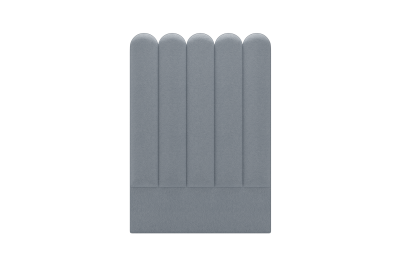

The first major consideration was the headboard frame, constructed from a laminated carpentry carcass. The designers asked for channel-stitched cushion padded at the front of the carpentry frame that softened the bed’s profile, curving gently inward at the two corners.

Power outlets and side tables became another layer of detail, ensuring everything was within easy reach without compromising aesthetics or functionality.

The sheer size and weight of the headboard was its own puzzle. At 3.63 meters, it became clear that lifting the headboard in one piece was asking for trouble: not only would it not fit in the lift which was smaller than most lifts we've delivered jobs to.

It would also be a potential hazard for our team’s backs. So we split it into three parts, designing it in a way that allowed for safe, easy assembly on site.

Incorporating live edge solid wood tables into this vision seemed straightforward at first. But while the initial design allowed the raw edge to show proudly, the wood had a natural, uneven underside that wasn’t so photo-friendly.

The solution was as tedious as it was rewarding, cushions below the irregularity of the wood had to be meticulously shaped to fit every contour, embracing the wood’s natural quirks while refining its presentation.

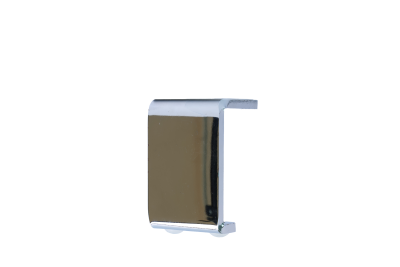

And then came the power outlets.

Overlooked by nearly everyone involved, their positioning suddenly became a visible detail with some unsightly gaps. It was a small slip, but in a project like this, every little detail counts. Thankfully, an on-site solution came together, covering up the gaps to keep the finish seamless.

In the end, this project was as much an exercise in detail as it was in craftsmanship. Every custom piece—be it the curved cushions, the separated headboard, or the carefully fitted outlets—taught us that sometimes, the smallest adjustments have the biggest impact.